A Guide to Designing a Set of Sheep Yards – Existing Infrastructure.

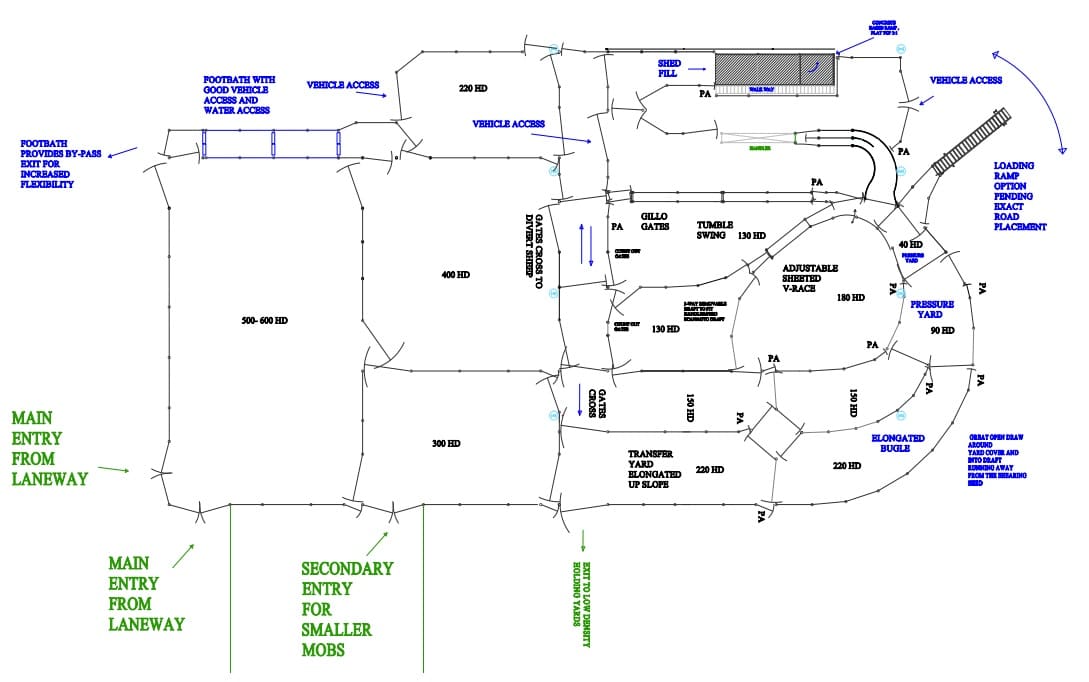

Think about the bigger picture: wire fences, gateways, and laneways can be moved to better suit stock flow and improve overall efficiency. Moving dirt is relatively inexpensive, so don’t let existing slopes limit your options. Paddocks and laneways significantly impact stock movement. The entrance to the shearing shed is only a small factor in yard design. Small alterations to the yard layout can easily accommodate the smooth flow of sheep into the shearing shed. Ensure there is adequate trough space for water access. Power and air supply should be available for drafters and handlers. Consider existing roads, drains, and pads for truck and vehicle access. Animal welfare should be the top priority, and opportunities to upgrade existing features within the project scope should be considered. Site North/North/North. To ensure the yards are efficient. Aim to have the working race and draft yards connect to holding areas or laneways to increase yard capacity. The orientation of the yards should account for the impact of light on sheep flow. Light can provide passive guidance, either encouraging or discouraging stock movement through clever design that utilises orientation.

For example, yards can use sheeted panels to increase passive pressure in winter when the sun creates more shade, or gates can be swung slightly higher than the panels so that when open, the rails don’t align, creating a contrast that exaggerates the opening and encourages better sheep flow. Northern and north-eastern light should be considered to promote sheep flow out of the draft and working race. Timing is crucial, as most commercial stock work occurs from dawn until mid-afternoon. Covered yards should have their shade movement accurately mapped throughout the year to ensure shadow lines do not negatively impact stock flow. The slope of the site is critical for stock movement. Provide access for trucks, mobile crutching trailers, dippers, preg scanners, etc. Prioritise animal welfare by using the natural aspects of the site to encourage stock flow, ensuring ethical sheep handling with minimal force.

Holding Yard Design Holding yards should accommodate the most common mob sizes, but this doesn’t mean the entire mob should fit into one yard (or the first entrance yard). Instead, ensure the flow into 1-2-3 yards from the laneway. A common mistake is trying to fit the entire mob into the entrance yard, making the yards larger, more expensive, and harder to use, as this requires restarting the sheep flow. Holding yards should Single / Double Working Race: The working race should be set back from the bugle diversion by 1-2 metres. This creates a ‘chute’ before the race starts, which holds 4-5 sheep at race width. As the race fills (with the help of a dog or stockperson), these sheep flow forward, filling the race to capacity. Laneways linking the exit draft yards provide flexibility. Running sheep have a larger positive influence on movement than those mingling encourage sheep to flow through into the main yards rather than be herded in and moved once full. The entrance is critical, and the design and size of holding yards should be determined after considering laneway width, length, mob size, and the orientation of existing features such as sheds, light, and slope. Distractions at the entrance can have a significant impact on the success of the entire design and should be carefully considered.

Depending on their size, holding yards are best designed as rectangular (offset from the main feed), which helps them fill by providing in a pen, and a serpentine design will encourage flow more effectively than a straight run out the gate. There should also be access to remove handlers or drafters if needed. PA gates should be positioned to place the stockperson in the best spot to encourage stock flow as they exit or enter yards. PA gates should not necessarily follow the shortest route, as this can increase stress on stock in particular pens. a sense of escape. As sheep enter through the entrance gates (size-specific), they flow into the yard. Once the yard fills to a ‘square’ shape, they begin to ring slightly and overflow into the next yard.

Diamond yards are not suitable for holding areas due to the poor open gate draw presented to the sheep. While effective in the working area, they limit use elsewhere. Holding yards can also function as water yards, and careful thought is needed to ensure water points positively influence yard filling and stock movement. Consideration should also be given to working dogs’ access to water without blocking stock flow.

Dogs should have easy access to water throughout the entire handling process, especially during critical times like drafting or race filling. Holding yards can have steeper slopes (1-3%), as sheep are generally left to empty out here, and with heavy rain, the yard will be cleaned if the pad is built to specifications. Consideration should also be given to effluent flow off the holding yard.